Top Stainless Hex Nuts Tips for Fasteners You Need to Know?

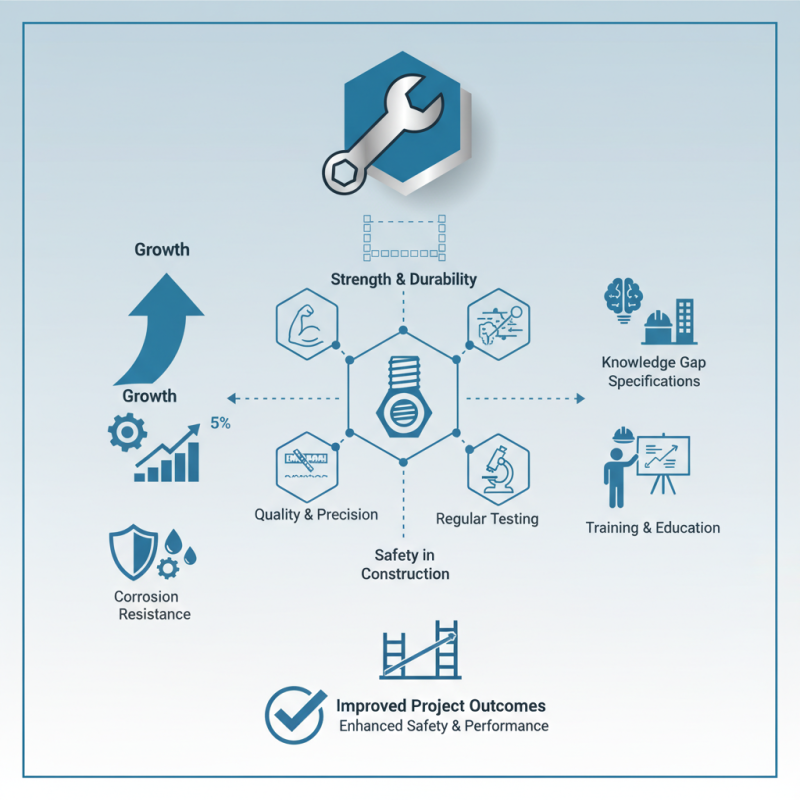

In the world of fasteners, Stainless Hex Nuts play a vital role in ensuring structural integrity. According to a recent industry report by Fastener World, the market for stainless fasteners is projected to grow by 5% annually. This growth reflects the increasing demand for corrosion-resistant materials in various applications. Leading expert Dr. Emily Rhodes emphasizes, “The strength and durability of Stainless Hex Nuts are crucial in maintaining safety standards in construction.”

Manufacturers are focusing on quality and precision. High-grade stainless steel is essential for optimal performance. However, not all hex nuts are created equal. Some products might not meet the necessary standards, which raises concerns among engineers. Regular testing is crucial to avoid failures in critical applications. Many users are unaware of the differences in material grades, which can lead to poor choices in sourcing.

Investing time to understand the specifications of Stainless Hex Nuts can save resources in the long run. There is still a gap in knowledge among some professionals regarding sourcing and selection. Companies should provide more training to their teams. The right hex nuts can make a significant difference in project outcomes. Addressing these issues enhances safety and performance across industries.

Understanding the Composition and Grades of Stainless Hex Nuts

Stainless hex nuts are pivotal in many fastening applications. Understanding their composition is key to selecting the right type for your project. Stainless steel typically comes in several grades, mainly 304 and 316. Grade 304 is widely used due to its corrosion resistance and good strength. In contrast, grade 316 offers superior resistance, particularly to chloride, making it ideal for marine applications.

The composition of these grades affects their mechanical properties. For example, grade 304 contains 8% nickel and 18% chromium. This blends well for indoor environments but may not fare well in harsh conditions. On the other hand, grade 316 includes molybdenum, providing enhanced durability but often at a higher cost.

It’s vital to consider these factors when choosing stainless hex nuts. Misjudging the grade needed can lead to premature failure, possibly causing costly downtimes. Some professionals overlook the right specifications. Always refer to reliable industry data, as various reports highlight a 20% failure rate associated with incorrect selections in critical applications. Awareness of these aspects helps in making informed choices.

Key Advantages of Using Stainless Steel Hex Nuts in Fasteners

Stainless steel hex nuts are essential in many fastening applications. They offer several key advantages that enhance performance and durability. One significant benefit is their resistance to corrosion. Unlike regular steel, stainless steel can withstand various environmental conditions without rusting. This makes them ideal for outdoor projects or moisture-rich environments.

Another important advantage is their strength. Stainless steel hex nuts maintain structural integrity under high tension. They can handle significant loads without failure. This reliability is crucial in construction and machinery. Moreover, their smooth finish allows for easy installation. However, improper handling might lead to stripping or cross-threading. Careful application is necessary.

Additionally, stainless steel hex nuts contribute to aesthetic appeal. They possess a polished surface that looks professional. Choosing the right size and grade is critical, though. Mismatching can lead to secure connections failing over time. Overall, embracing stainless steel hex nuts can elevate a project's reliability and lifespan.

Critical Applications of Stainless Hex Nuts in Various Industries

Stainless hex nuts are essential fasteners in various industries. They are commonly used in construction, automotive, and aerospace applications. These nuts offer excellent resistance to corrosion, making them suitable for harsh environments. Their durability ensures reliability, especially in critical settings.

Tips for selecting stainless hex nuts include checking the grade of stainless steel. Different grades have varying strength and corrosion resistance. Always consider the specific application. For high-temperature environments, choose nuts designed to withstand such conditions.

Size matters too. Ensure the nut fits perfectly with the corresponding bolt. Additionally, proper installation is crucial for performance. Avoid over-tightening, as this can lead to stripped threads. Regular inspections can prevent failure in critical applications. Understanding their potential weaknesses can lead to proactive maintenance. Each application has its nuances, so don't underestimate the importance of choosing the right fastener.

Important Considerations for Selecting the Right Stainless Hex Nuts

When selecting stainless hex nuts, consider material grade and corrosion resistance. According to industry reports, Grade 18-8 stainless steel is common for general applications. It offers good strength and corrosion resistance, often sufficient for indoor use. However, in harsher environments, higher grades like 316 may be necessary. These are more resistant to chemicals and saltwater but can be more expensive.

Thread size is another critical factor. Ensure compatibility with the bolts you plan to use. Mismatched sizes can lead to stripping or loosening over time. Reports indicate that improper sizing accounts for up to 30% of fastener failures. Also, surface finishes matter. A smooth finish reduces friction, but it may not provide the grip needed in some applications. Always assess these nuances during your selection process. It’s essential to weigh costs against performance for your specific needs.

Top Stainless Hex Nuts: Key Considerations

This bar chart illustrates the key considerations for selecting the right stainless hex nuts, rated on a scale from 1 to 10. The factors include material quality, thread type, sizing accuracy, corrosion resistance, and load capacity.

Maintenance and Best Practices for Long-Lasting Stainless Hex Nuts

When it comes to maintaining stainless hex nuts, understanding the environment is crucial. Factors like humidity, temperature, and exposure to chemicals can affect their longevity. Regular inspection is key. Look for signs of corrosion or wear. Sometimes, a simple cleaning can restore their shine and function.

Lubrication is another important practice. A light coating can prevent galling and make future removals easier. Be cautious, though. Too much lubricant can attract dirt and grime. Keep the threads clean to ensure a snug fit.

Proper storage is often overlooked. Keep hex nuts in a dry place. Use containers that allow airflow to prevent moisture buildup. It may seem tedious, but investing time in maintenance pays off in durability. Small actions can prevent larger issues down the line. Being proactive matters.

Top Stainless Hex Nuts Tips for Fasteners You Need to Know

| Tip | Description | Best Practice |

|---|---|---|

| Choose the Right Size | Ensure the hex nut matches the diameter of the associated bolt. | Measure the bolt before selecting a hex nut. |

| Consider Material Quality | Opt for high-quality stainless steel for better corrosion resistance. | Research grades (e.g., A2, A4) for appropriate applications. |

| Proper Torque Application | Use a torque wrench to apply the correct tightening force. | Reference manufacturer specifications for torque settings. |

| Regular Inspections | Check for signs of wear, corrosion, or loosening over time. | Schedule routine maintenance checks on hardware. |

| Use of Lock Nuts | Consider using lock nuts to prevent loosening from vibrations. | Employ lock nuts in high-vibration environments. |

| Avoid Over-Tightening | Over-tightening can cause damage and reduce the lifespan of hex nuts. | Follow torque guidelines to prevent overstressing the connection. |