Top 10 Tips for Choosing Stainless Hexagon Bar for Projects?

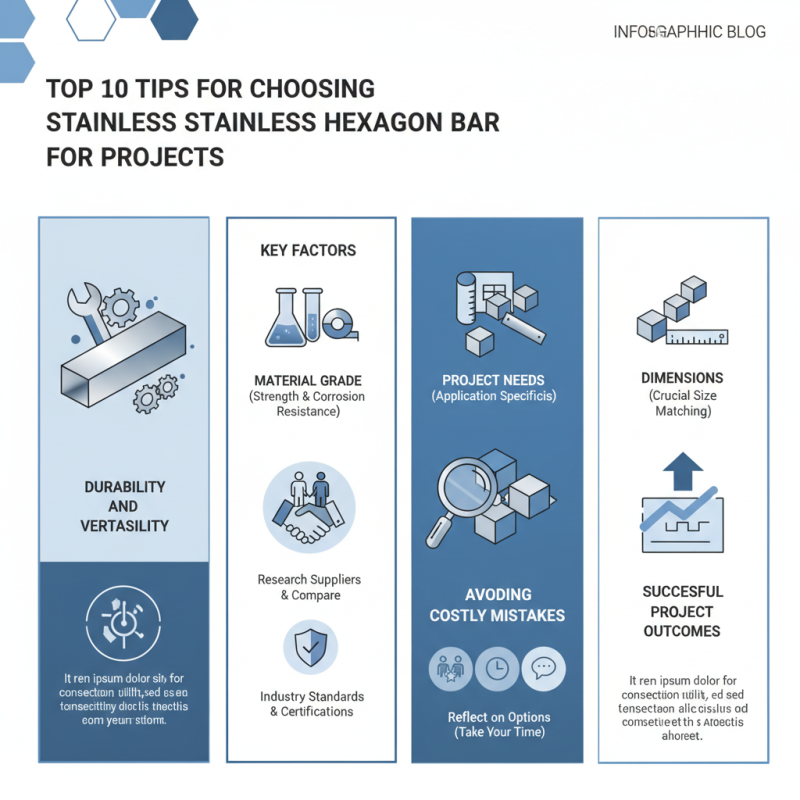

Choosing the right material for projects can be challenging. Among various options, Stainless Hexagon Bar stands out due to its durability and versatility. It is ideal for a range of applications, from manufacturing to construction. However, not every Stainless Hexagon Bar is created equal.

When selecting the right bar, it is essential to consider several factors. The material's grade affects strength and corrosion resistance. Your specific project needs will guide your choice. Don't overlook dimensions, as the right size is crucial. Each project has its requirements, and matching those needs is important.

Making mistakes in material selection can lead to costly issues. Investigate different suppliers and compare their offerings. Ensure you understand industry standards and certifications. A hasty choice may not yield the desired results. Take your time to reflect on your options before proceeding.

Benefits of Stainless Hexagon Bar in Engineering Applications

Stainless hexagon bars have gained popularity in engineering applications due to their unique properties. The material offers excellent corrosion resistance, making it ideal for harsh environments. According to a recent report by the International Stainless Steel Forum, about 70% of stainless steel used in construction is for components requiring high durability. This figure highlights the significance of using quality materials like stainless hexagon bars.

Another advantage is their versatility. Engineers often opt for these bars in machine parts and structural applications. Their hexagonal shape allows for easy integration and bolting. The material's strength-to-weight ratio is also noteworthy. Studies indicate that stainless hexagon bars can withstand substantial loads while remaining lightweight.

However, not all stainless hexagon bars are created equal. Selecting the right grade is crucial. Some grades may lack the desired mechanical properties. Identifying the ideal specifications can be complex. It requires research and sometimes a trial-and-error approach. Engineers often face challenges in balancing cost and performance.

Key Material Properties of Stainless Steel for Project Durability

Stainless steel offers unique properties that enhance project durability. This metal is resistant to rust and corrosion due to its chromium content, which forms a protective layer. According to the Stainless Steel Institute, the remarkable strength-to-weight ratio makes stainless steel a preferred choice across diverse sectors. The toughness of this alloy provides resilience under various stress conditions.

When selecting stainless hexagon bars, consider the grade of stainless steel. Higher grades like 316 offer better corrosion resistance. This is vital for marine or chemical applications. A lower grade may suffice for indoor projects, but unexpected rust can undermine long-term durability.

Moreover, evaluate the bar's tensile strength, which varies by grade. For instance, 304 stainless steel has a tensile strength of about 580 MPa, suitable for many structural applications. Be aware that some projects may demand higher strength. Sometimes, being cost-effective can lead to oversights.

Ensure to assess your project requirements before making a decision. Opting for the right hexagon bar means balancing cost and durability. Don't compromise on quality to save a few bucks. Remember, investing in the right material saves money in the long run.

Factors Influencing the Selection of Diameter and Length

When choosing the right diameter and length for stainless hexagon bars, there are key factors to consider. The diameter can greatly influence the bar's strength. Thicker bars tend to have higher tensile strength but may not be suitable for all applications. It’s essential to evaluate the load requirements. A bar that is too thick may also add unnecessary weight to your project.

Length is another critical aspect. A longer hexagon bar allows for more versatility in design. However, it's vital to think about the dimensions of your project space. A bar that's too long can be cumbersome. Cutting it down may compromise its structural integrity. Planning your design with proper measurements is crucial.

Material properties also play a role in selection. Different grades of stainless steel have varying corrosion resistance and strength. If your project requires high durability, consider those properties closely. Reflecting on application needs can save time and money in the long run. Choosing the right diameter and length is about balancing strength and practicality.

Understanding Corrosion Resistance Ratings for Stainless Hexagon Bar

When choosing stainless hexagon bars, understanding corrosion resistance ratings is key. Stainless steel is popular due to its durability and strength. However, not all stainless steels are created equal. For instance, grades like 304 and 316 offer different levels of corrosion resistance. Knowing their properties can drastically affect your project’s outcome.

Corrosion resistance is essential in many environments, particularly in marine or industrial settings. The 316 grade contains molybdenum, enhancing its resistance to saltwater. In contrast, 304 is suitable for less harsh settings. This choice can be challenging. Sometimes, projects may be over budget, meaning compromises are necessary. This is where understanding these ratings becomes crucial.

Consider how the stainless hexagon bar will be used. Will it face harsh chemicals or high humidity? Each environment poses unique challenges. Ignoring these factors may lead to premature failure. Reflecting on the specific needs can prevent expensive mistakes. Choosing wisely based on corrosion resistance can enhance the longevity of your project significantly.

Cost Considerations and Supplier Options for Bulk Purchases

When considering bulk purchases of stainless hexagon bars, cost is a primary factor. According to a recent industry report, the average price of stainless steel has increased by approximately 10% over the past year. This fluctuation means buyers should stay updated on market trends. Long-term contracts may offer some price stability, but evaluating supplier options is essential.

For projects requiring consistency, sourcing from reliable suppliers ensures quality. Compare at least three suppliers to gauge pricing and terms. Many suppliers offer discounts on bulk orders, which can significantly impact the project budget. It’s crucial to clarify whether the quoted price includes shipping and handling to avoid unexpected costs.

Tip: Consider total lifecycle costs. In addition to the purchase price, account for maintenance and longevity. High-quality materials may have a higher upfront cost but result in savings over time.

Don’t overlook supplier reputation. A lower price from an unknown supplier might lead to subpar quality. Research reviews and seek recommendations. Trustworthy suppliers often provide certifications that ensure quality standards are met. This diligence can prevent costly project delays and rework.