Unveiling the Technical Specifications of the Best Step Bit for Ultimate Precision

In the realm of precision drilling, the choice of tools significantly impacts the quality and efficiency of projects across various industries, from construction to manufacturing. Among these tools, the Step Bit has garnered attention for its versatility and precision. According to a report by Grand View Research, the global power tools market size is expected to reach $45.36 billion by 2025, with a growing demand for specialized drilling equipment like step bits, driven by advancements in engineering and technology. These multi-tiered bits offer distinct advantages, such as reducing the need for multiple drill sizes and improving accuracy in hole sizing. As we delve into the technical specifications of the best step bits, we will explore the features that contribute to ultimate precision and why they are becoming a staple in both professional and DIY settings.

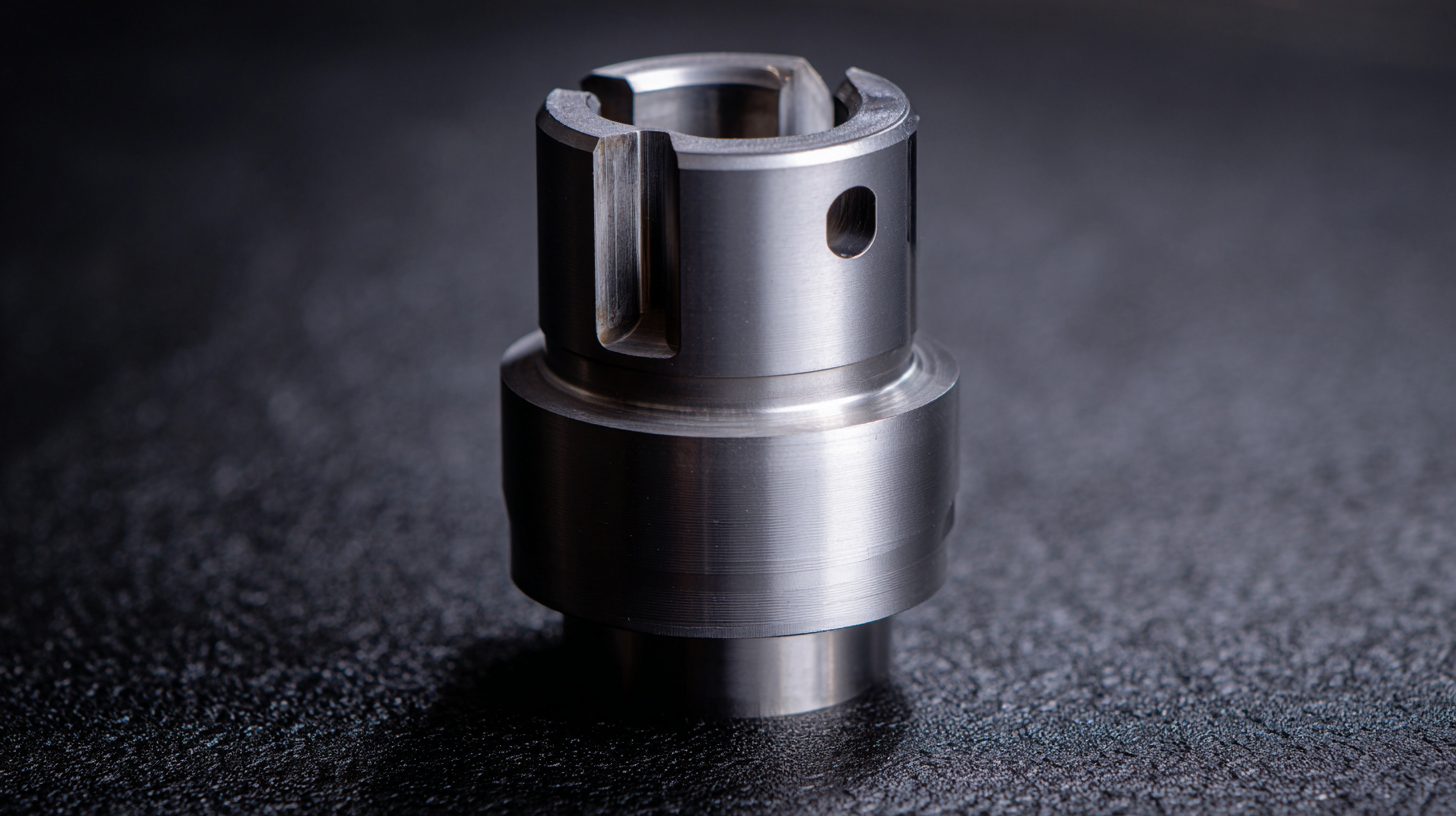

Understanding Step Bits: A Comprehensive Overview of Technical Specifications

When it comes to achieving ultimate precision in drilling, understanding the technical specifications of step bits is essential.

Step bits, designed with various diameters along their length, provide versatility in creating holes of different sizes while ensuring clean cuts. The common materials used for these bits are high-speed steel (HSS) and cobalt, which offer durability and heat resistance, essential for prolonged use. The cutting angles, typically around 45 degrees, facilitate efficient chip removal and prevent binding during operation.

Step bits, designed with various diameters along their length, provide versatility in creating holes of different sizes while ensuring clean cuts. The common materials used for these bits are high-speed steel (HSS) and cobalt, which offer durability and heat resistance, essential for prolonged use. The cutting angles, typically around 45 degrees, facilitate efficient chip removal and prevent binding during operation.

Tip: When selecting a step bit, consider the material you're drilling into. Opt for bits with titanium coating for softer materials, while cobalt step bits are ideal for tougher metals. Additionally, always check the flutes' design; spiral flutes enhance chip ejection, thereby improving overall performance.

Another crucial specification to look at is the size range of the bit. A broader range allows for more flexibility in drilling tasks. Ensure that the increment between step sizes is manageable; this aids in maintaining precision and reduces the risk of drilling errors.

Tip: It’s beneficial to have a step bit set that offers multiple sizes. This not only increases efficiency but also ensures you have the right tool for various projects without the need for constant changes.

Key Features to Look for in Top-Rated Step Bits

When selecting the best step bit for precision drilling, several key features should be at the forefront of your consideration. First and foremost, the material and coating of the step bit significantly influence its durability and performance. High-speed steel (HSS) is a popular choice due to its resilience, while cobalt-coated bits offer enhanced heat resistance, making them ideal for tougher materials. Additionally, titanium or nitride coatings can reduce friction and improve cutting efficiency, allowing for cleaner holes and extended tool life.

Another crucial aspect to evaluate is the bit's design and increment sizing. A well-engineered step bit should feature precise incremental steps that enable accurate hole sizes without needing multiple tools. Look for bits with sharply defined cutting edges, as these will reduce the likelihood of wandering and ensure a more precise cut. Furthermore, some top-rated step bits come with built-in drill guides, providing additional stability and accuracy, making them a valuable addition to any toolkit for professionals and DIY enthusiasts alike.

Precision Matters: Evaluating Tolerance Levels in Step Bit Designs

When it comes to drilling, the precision of the tool can make all the difference in achieving the desired results. Step bits are increasingly popular for their versatility and effectiveness; however, not all step bits are created equal. Evaluating the tolerance levels in their designs is crucial for ensuring that they meet specific operational needs. High-quality step bits are engineered with tighter tolerances, allowing for cleaner and more accurate holes, essential in tasks where precision is paramount.

Moreover, different applications require varying degrees of precision, which is where the significance of tolerance levels comes into play. For instance, in automotive or aerospace industries, where the fit of components can be critical, choosing a step bit that offers finer tolerances can prevent costly errors. By understanding the implications of these tolerances, users can select the ideal step bit that aligns with their project requirements, facilitating smoother workflows and enhancing overall efficiency.

Material Selection: How the Right Composition Enhances Performance

When it comes to selecting the best step bit for ultimate precision, the choice of material cannot be overstated. Step bits are often crafted from high-speed steel (HSS), cobalt, or titanium-coated steel, each offering unique advantages in durability and performance. High-speed steel, for example, provides excellent toughness and wear resistance, making it ideal for drilling through metals. On the other hand, cobalt bits are specifically designed for tougher materials, retaining their hardness even at high temperatures, which is crucial for maintaining sharpness during prolonged use.

Furthermore, the surface treatment of step bits plays a significant role in enhancing their efficiency. Titanium coatings reduce friction, resulting in smoother cuts and prolonged life for the bit. This type of treatment also aids in heat dissipation, which minimizes the risk of overheating and bit damage. Selecting the right material and coating can make a substantial difference in achieving a cleaner finish and faster drilling speeds, confirming that material composition is a key factor in maximizing a step bit's performance for various applications.

Unveiling the Technical Specifications of the Best Step Bit for Ultimate Precision

| Material | Coating | Drilling Range (mm) | Flute Design | Application |

|---|---|---|---|---|

| High-Speed Steel (HSS) | Titanium Nitride (TiN) | 3 - 20 | Spiral Flute | Wood and Plastic |

| Cobalt Steel | Black Oxide | 4 - 22 | Straight Flute | Metal and Aluminum |

| Carbide Tipped | Diamond Coated | 5 - 25 | Double Flute | Hard Materials |

| High-Speed Steel with Cobalt | Zinc Coating | 6 - 30 | Screw Flute | Composites |

| M2 High Speed Steel | TiAlN Coating | 8 - 32 | Variable Pitch Flute | Stainless Steel |

Comparing Popular Brands: Who Offers the Best Step Bit Technology?

When it comes to selecting the best step bit for precision drilling, comparing popular brands can lead to significant advantages in terms of quality and performance. Each brand brings its unique technology to the market, impacting factors like material compatibility and drill speed. It's essential to evaluate how these specifications align with your specific needs, whether you're working with softer metals or harder materials like stainless steel.

Tips: Before making a purchase, consider the specifics of your projects. Look for a step bit designed for various materials to enhance versatility. Moreover, assess the brand's reputation based on user reviews and performance metrics. Investing in a reliable step bit can save you time and enhance the accuracy of your work.

Another aspect to consider is the construction material of the step bit itself. Some brands utilize advanced coatings that reduce friction and increase durability, allowing for cleaner cuts and longer tool life. This can be particularly beneficial in demanding applications where precision is paramount.

Tips: Always check for engineered features such as sharp cutting edges and flute design that can enhance chip removal, keeping the bit from binding during operation. Lastly, ensure that you're equipped with the right power tools that complement the step bit for optimal results.