What is Steel Scaffolding for Sale and How to Choose the Best?

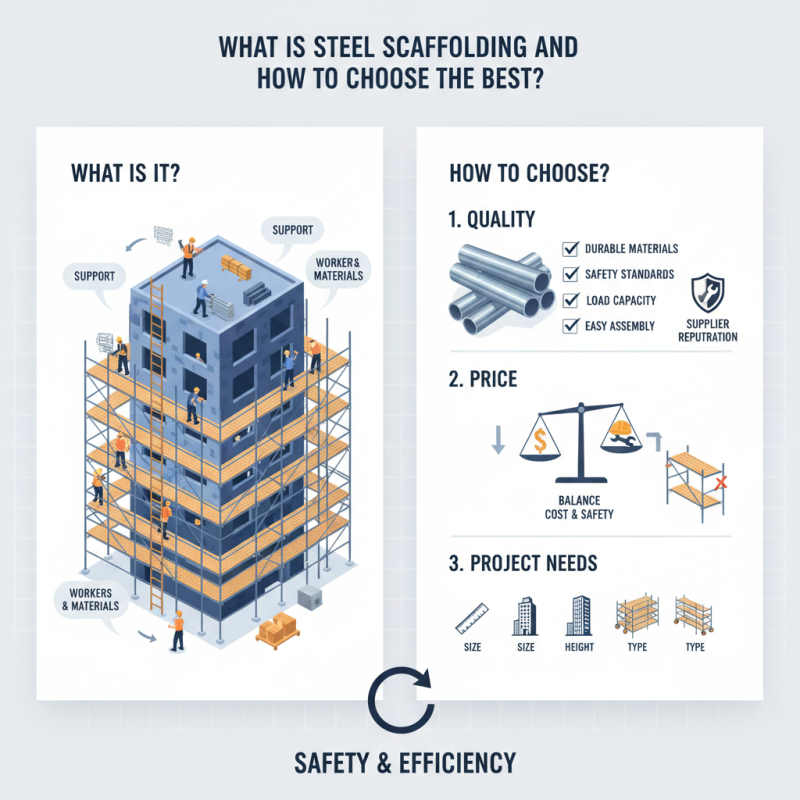

steel scaffolding for sale plays a crucial role in construction projects. It provides support and stability for workers and materials high above the ground. Choosing the right scaffolding is more than just a purchase. It requires careful consideration of various factors.

When browsing options, quality is essential. Look for scaffolding made from durable materials. Ensure that it meets safety standards. Inspect features like load capacity and assembly ease. Pay attention to the supplier's reputation. A well-reviewed vendor can be a sign of good products and reliability.

Price is another key consideration. While low-cost options may seem appealing, they can compromise safety. Balance cost with quality. Think about your specific project needs. Size, height, and type of scaffolding matter. Reflect on your choices. The right equipment can make a significant difference in both safety and efficiency.

Definition and Overview of Steel Scaffolding

Steel scaffolding serves as a temporary structure that provides support for construction and maintenance work. It allows workers to access elevated areas safely. Reports indicate that the global scaffolding market is projected to reach $65 billion by 2027, driven by rapid urbanization. This growth highlights the increasing reliance on efficient scaffolding solutions.

Choosing the right steel scaffolding involves considering various factors. Load capacity is crucial; some systems support up to 2,000 pounds, suitable for heavy equipment. Safety standards are another critical aspect. According to the Occupational Safety and Health Administration (OSHA), compliance with safety regulations reduces job site accidents significantly. However, some contractors overlook these details, impacting work efficiency.

Inspection is vital but often neglected. Regular checks can reveal structural weaknesses, reducing risks. Not all scaffolding systems are designed equally; material quality can vary widely. Awareness of the potential for corrosion and fatigue is necessary. The best choice aligns with specific project needs while adhering to safety guidelines. Balancing cost and quality is a common challenge. It's essential to reflect on these elements when selecting scaffolding solutions.

Key Benefits of Using Steel Scaffolding in Construction

Steel scaffolding is a popular choice in construction due to its numerous benefits. One key advantage is durability. Steel scaffolding can withstand harsh weather conditions, reducing the risk of project delays. According to industry reports, steel scaffolding can last up to 20 years with proper maintenance. This longevity can lead to significant cost savings over time, making it a wise investment for builders.

Another important benefit is safety. Steel scaffolding systems provide excellent stability and support. Research indicates that about 42% of construction injuries are caused by falls from heights. Using steel scaffolding can help mitigate these risks. The robust nature of steel ensures that workers have a secure platform while performing tasks at elevated levels. However, it is crucial to properly train workers in using and assembling these scaffolding systems.

Moreover, steel scaffolding is versatile. It can be adapted to various construction needs, from residential buildings to large commercial projects. This adaptability allows for efficient use of resources. However, improper assembly or maintenance can lead to accidents. Workers must consistently check for signs of wear, such as rust or damage. Recognizing these issues early can prevent costly mistakes and ensure safety on job sites.

Factors to Consider When Choosing Steel Scaffolding

Choosing the right steel scaffolding is crucial for safety and efficiency. Various factors come into play within this decision. One must consider the load capacity. It’s essential that the scaffolding can support the weight of workers and materials. Overloading can lead to severe incidents.

Another significant aspect is the height of the scaffolding. The project type often dictates how tall the scaffold needs to be. If it’s too short, workers may struggle to reach higher areas. Conversely, if it's too high, it can create stability issues. Always prioritize safety features like guardrails and base plates.

Tips: Inspect for rust or damage. Also, check for proper assembly instructions. A well-set structure reduces risks. Look closely at material quality; thickness matters. Think about portability too. If you need to move it often, lightweight options are ideal. Remember that cheaper isn't always better. Quality often ensures a safer and more reliable experience.

Types of Steel Scaffolding Available in the Market

When buying steel scaffolding, it’s essential to understand the types available. There are several options to consider. Each type serves different purposes based on the project needs. Common types include modular scaffolding, frame scaffolding, and rolling scaffolding.

Modular scaffolding is versatile. It can be customized for various heights and widths. This flexibility is a significant advantage. Frame scaffolding is often easy to set up. It's a choice for straightforward projects. Rolling scaffolding is perfect for tasks that require mobility. It allows workers to move from one area to another with ease.

**Tip:** Always check load capacity. It’s crucial to ensure safety. Overloading scaffolding can lead to accidents.

Choosing the right type of scaffolding is not always clear-cut. Consider the site conditions and the scope of work. Different projects might require different setups. Don’t forget that maintenance is vital. Regular inspections can prevent accidents. A well-maintained scaffold is a safe scaffold.

**Tip:** Take into account weather impacts. Steel scaffolding can corrode if not treated properly. Protecting your investment is key.

Types of Steel Scaffolding Available in the Market

Safety Standards and Regulations for Steel Scaffolding

When selecting steel scaffolding, safety standards and regulations are paramount. According to OSHA, scaffolding accounts for 20% of fall-related deaths in construction. Compliance with safety guidelines can reduce accidents significantly. The use of sturdy materials is crucial. Steel scaffolds should have a minimum yield strength of 36 KSI, ensuring they can support heavy loads.

Proper assembly and maintenance are equally important. The American National Standards Institute (ANSI) outlines specifications for scaffold design and safety. These standards include regular inspections and training for workers. Many accidents arise from improperly assembled scaffolds or the absence of guardrails. In fact, nearly 50% of scaffolding-related injuries are due to falls.

To make informed choices, consider local regulations too. They might have additional requirements. Lack of awareness can lead to serious consequences. Always prioritize safety over cost. Investing in quality scaffolding can protect workers and enhance site safety.