10 Reasons Why Saw Saw Blades are Essential for Your Manufacturing Needs

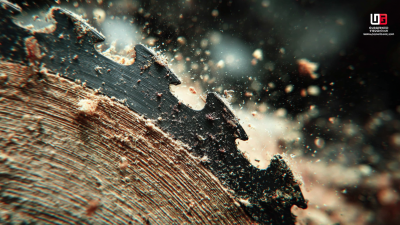

In the fast-paced world of manufacturing, efficiency and precision are paramount, and choosing the right tools is crucial for achieving both. Among these tools, Saw Saw Blades stand out as an essential component for various cutting and shaping tasks.

According to a recent report by the Freedonia Group, the global market for saw blades is expected to reach $1.5 billion by 2024, reflecting an increasing demand driven by the manufacturing sector's growth. With advancements in material technology and blade design, today's saw blades offer better durability and performance.

This blog will explore ten compelling reasons why Saw Saw Blades are indispensable for modern manufacturing needs, ensuring that companies can enhance productivity, improve product quality, and meet the evolving demands of their industries.

The Role of Saw Blades in Increasing Manufacturing Efficiency and Precision

In modern manufacturing, the significance of saw blades cannot be overstated. They play a crucial role in enhancing both efficiency and precision, which are essential for high-quality output. Advanced saw solutions, especially in vertical band saw technology, allow for improved cutting accuracy and operational flexibility, catering to different manufacturing needs from manual to fully automatic processes. This versatility is key in meeting the demands of industries such as aerospace and medical, where precision is paramount.

To maximize efficiency, manufacturers should prioritize the selection of the right saw blade for their specific tasks. Choosing blades designed for specific materials can greatly reduce waste and enhance cutting speed. For instance, saws tailored for lead-free brass or lightweight core materials not only improve material utilization but also foster a smoother workflow.

To maximize efficiency, manufacturers should prioritize the selection of the right saw blade for their specific tasks. Choosing blades designed for specific materials can greatly reduce waste and enhance cutting speed. For instance, saws tailored for lead-free brass or lightweight core materials not only improve material utilization but also foster a smoother workflow.

Additionally, regular maintenance of saw blades is vital for consistent performance. Keeping blades sharp and in good condition ensures they operate at peak efficiency, minimizing downtime and enhancing overall productivity. Investing in high-quality saw blades, as well as understanding their maintenance needs, can make a substantial difference in manufacturing success.

Key Factors Influencing Saw Blade Selection for Various Materials

When selecting saw blades for manufacturing needs, several key factors must be considered to achieve optimal performance across various materials. Material type significantly influences the choice of saw blade, as different materials exhibit distinct characteristics. For instance, a study by the Woodworking Machinery Industry Association reports that using specialized blades for hardwood can improve cutting efficiency by up to 30%, demonstrating that blade selection tailored to the material can result in substantial productivity gains.

Additionally, the tooth design plays a critical role in the effectiveness of the cutting process. According to a report from the Metal Cutting Institute, blades with fewer, wider teeth are ideal for cutting softer materials, as they offer faster chip removal and reduce the risk of blade binding. Conversely, finer tooth designs yield smoother finishes on harder materials, thereby enhancing precision. Understanding these nuances ensures that manufacturers select the appropriate saw blades, ultimately leading to increased operational efficiency and lower production costs.

10 Reasons Why Saw Saw Blades are Essential for Your Manufacturing Needs

Analyzing the Cost-Effectiveness of High-Quality Saw Blades in Production

The manufacturing industry is witnessing a significant rise in the demand for high-quality saw blades, with the global bimetal saw blade market projected to grow from $570 million in 2025 to $868 million by 2032, reflecting a robust annual growth rate of 6.2%. This increase highlights the crucial role that superior saw blades play in enhancing production efficiency and cost-effectiveness. High-quality saw blades ensure precise cutting and longer life, which ultimately reduces the frequency of blade replacements and maintenance costs. As manufacturers seek to maximize productivity while controlling expenses, investing in premium saw blades has become an essential strategy.

Moreover, the integration of big data analytics into the quality management processes within the steel industry is transforming operational efficiency. By utilizing big data, manufacturers can model process parameters to predict quality outcomes more accurately and dynamically optimize compositional control models. This advancement not only enhances overall product quality but also streamlines manufacturing workflows, ensuring that companies can meet market demands without compromising on standards. Thus, as the industry evolves, the importance of reliable saw blades, supported by innovative quality management practices, cannot be overstated.

Industry Trends: Innovations in Saw Blade Technology for Enhanced Performance

In the realm of manufacturing, innovations in saw blade technology are reshaping industry standards and driving growth. The upcoming Power Saw & Blade Market forecast from 2024 to 2029 indicates a significant rise in demand for polycrystalline diamond (PCD) saw blades and customized cutting solutions. This trend reflects the growing need for precision and durability in cutting applications, ensuring that manufacturers can meet their production goals efficiently.

Moreover, the global saw blades market is projected to surge from USD 16.8 billion in 2025 to USD 26.4 billion by 2035, highlighting a robust CAGR fueled by the increasing demand in both construction and manufacturing sectors. As technology evolves, cutting fluids are becoming integral in enhancing machining efficiency and extending tool life, further emphasizing the importance of advanced saw blade technology. These innovations not only improve performance but also contribute to sustainable manufacturing practices, aligning with the industry's shift towards energy-efficient solutions.

Safety Standards and Best Practices for Using Saw Blades in the Workplace

When utilizing saw blades in manufacturing, adhering to safety standards and best practices is of paramount importance. According to a report by the Occupational Safety and Health Administration (OSHA), in 2021 alone, over 65,000 injuries were recorded in the woodworking industry, many of which involved improper use of cutting tools. Ensuring that employees are trained in safe handling practices can significantly reduce the risk of accidents. Proper training includes understanding the specific hazards associated with different types of saw blades and implementing lock-out/tag-out procedures to control equipment during maintenance.

In addition to training, regular equipment maintenance and inspection play a crucial role in workplace safety. The National Institute for Occupational Safety and Health (NIOSH) suggests that an estimated 30% of workplace saw-related injuries can be prevented by routine checks and timely blade replacements. Manufacturers should establish a stringent maintenance schedule that includes checking for blade wear, ensuring proper alignment, and validating safety features. By fostering a culture of safety and diligence, companies not only protect their workforce but also enhance productivity through minimized downtime and fewer disruptions caused by accidents.

Related Posts

-

Essential Techniques for Maximizing the Use of Saw Blades

-

Exploring the Future of Metal Cutting Technologies and Advantages of Best Metal Saw Blades in 2025

-

Ultimate Guide to Choosing the Best Saw Blades for Wood in Your Global Sourcing Strategy

-

Ultimate Guide to Selecting the Best Hole Saw for Stainless Steel Applications

-

Mastering Precision Cuts: A Comprehensive Guide to Choosing the Best Jigsaw Blades for Any Project

-

What Makes the Best Hole Saw Drill Bit Essential for Every Professional