Tips for Sourcing High Quality Recip Saw Blades from Manufacturers

In the ever-evolving construction and manufacturing industries, the demand for high-quality tools is paramount. Among these essential tools, Recip Saw Blades play a vital role in enhancing operational efficiency and precision. According to a recent report by IBISWorld, the saw blade manufacturing industry has seen a steady growth of approximately 3.2% annually, highlighting the increasing reliance on versatile cutting tools. As contractors and tradespeople strive to improve productivity and reduce downtime, sourcing high-quality Recip Saw Blades has become a critical factor for success.

Furthermore, the market dynamics indicate that the quality of blades directly impacts the performance of reciprocating saws in various applications, from demolition to plumbing tasks. A study published by Research and Markets emphasizes that the right choice of Recip Saw Blades can lead to a 20-30% improvement in cutting speed and efficiency. This blog will provide essential tips for sourcing Recip Saw Blades directly from manufacturers, ensuring that professionals can make informed decisions and invest in tools that meet their specific needs.

Understanding the Importance of Quality Recip Saw Blades in Your Projects

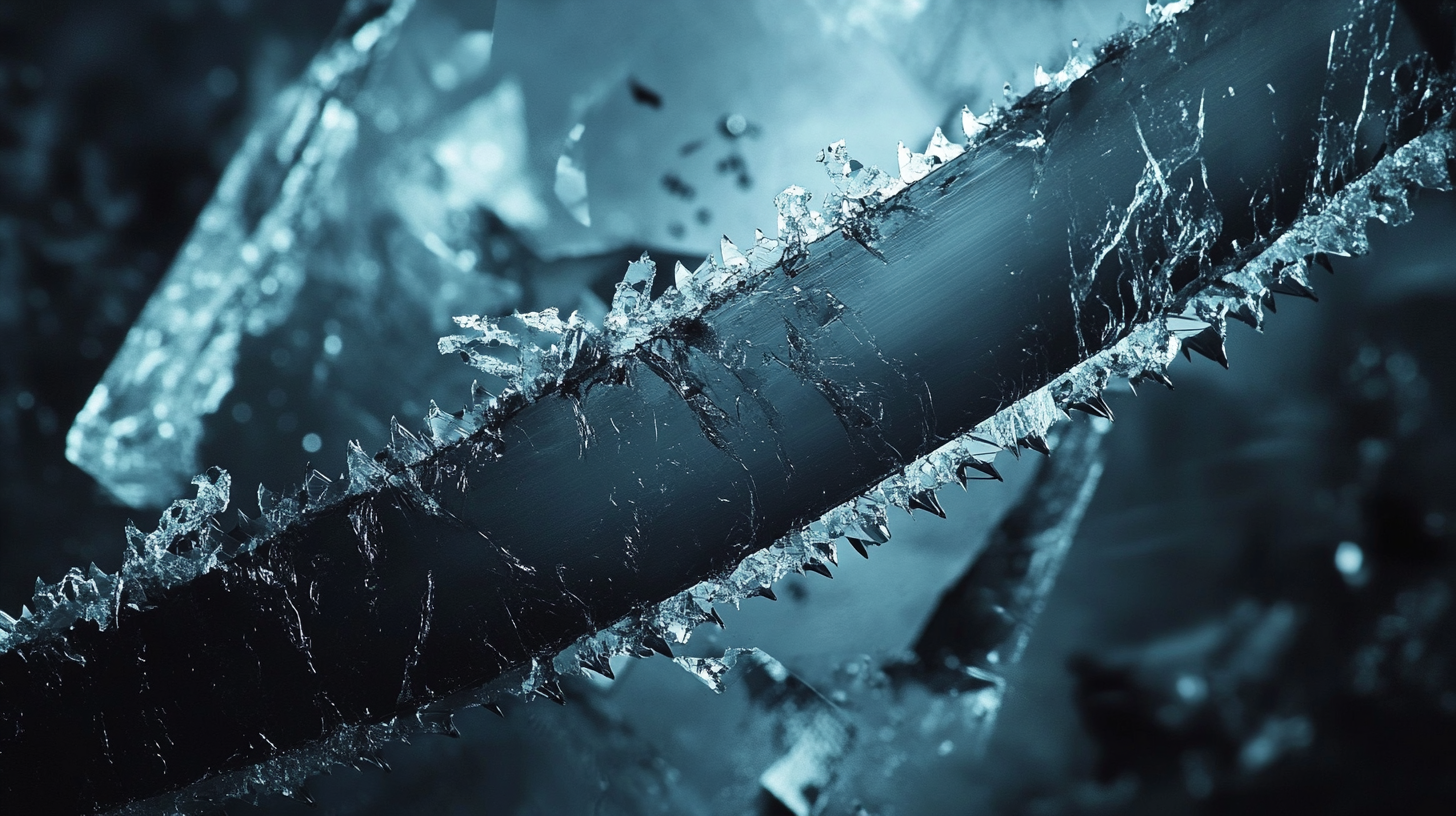

When it comes to sourcing high-quality reciprocating saw blades, understanding the significance of quality in your projects is paramount. Quality blades not only enhance cutting efficiency but also ensure safety and durability during use. For instance, the latest models feature advanced tooth designs that improve cutting speed and reduce wear over time. Recent innovations have seen blades optimized for thicker metals, which allow users to tackle more challenging materials with confidence. The performance metrics of these blades reveal notable improvements in cutting precision and speed. Blades featuring high tooth counts, specifically designed for aggressive cuts, have gained traction among professionals. Such designs, with specifications like 8 teeth per inch, are on par with leading competitors in terms of aggression and efficiency. This attention to detail not only benefits construction professionals but also rescue personnel who rely on superior cutting tools during critical operations. Moreover, the advent of specialized blade technologies, such as those employing carbide tips, represents a significant leap in material science. These blades are engineered to withstand extreme conditions and cut through tough materials like ultra-high-strength steel, dramatically improving productivity and reducing downtime. For manufacturers looking to improve their tool offerings, sourcing from suppliers that prioritize quality and innovation can be the key to enhancing overall project outcomes.

Key Features to Look for in High-Quality Recip Saw Blades

When sourcing high-quality reciprocating saw blades, it's essential to focus on specific features that can significantly impact performance and durability. One of the key features to consider is the material of the blade. High-carbon steel blades are suitable for general wood cutting, while bi-metal blades combine high-speed steel and high-carbon steel, offering better flexibility and longer lifespan for tougher applications. For cutting through metal or dense materials, carbide-tipped blades are often the best choice due to their exceptional hardness and ability to maintain sharpness over extended use.

Another important factor is the tooth design and configuration. Blades with a variable tooth pitch can reduce vibration and enhance cutting efficiency, making them ideal for various materials. Blades featuring larger teeth are beneficial for fast cuts in wood, whereas blades with finer teeth are essential for more intricate cuts or tougher materials. The tooth count must match the intended use; for instance, a lower tooth count allows for quicker, rough cuts, while a higher count is necessary for smoother finishes.

Lastly, blade thickness plays a critical role in determining the performance of reciprocating saw blades. Thicker blades provide stability and reduce the risk of bending or breaking during heavy-duty tasks, making them suitable for rigorous applications. Furthermore, considering the blade's length is crucial as it impacts the cutting depth. In summary, by focusing on the blade material, tooth design, and thickness, you can ensure a successful sourcing process, leading to enhanced performance and longevity in your projects.

Assessing Manufacturers: Reputation, Certifications, and Reviews

When sourcing high-quality recip saw blades from manufacturers, it is crucial to assess the manufacturers based on their reputation, certifications, and reviews. A strong reputation can indicate a manufacturer’s reliability and product quality, making it an essential factor in your decision-making process. According to industry reports, manufacturers with a proven track record often enjoy increased customer loyalty, resulting in a higher return on investment compared to lesser-known brands.

Certifications play a vital role in ensuring that a manufacturer adheres to industry standards and practices. Certifications such as ISO 9001 not only reflect a commitment to quality management but also inspire confidence in the end consumer. In the competitive landscape of saw blade manufacturing, certified products often command higher prices, as they meet stringent safety and performance requirements. For instance, industry analysis shows that certified products can be 25-30% more effective in performance tests, underscoring the importance of seeking manufacturers with proper accreditation.

Reviews from previous customers provide additional insight into a manufacturer’s quality and service. Analyzing customer feedback on platforms like industry forums and social media can reveal critical information about product lifespan, cutting efficiency, and overall satisfaction. Research indicates that trustworthy reviews can significantly influence purchasing decisions, with 79% of consumers trusting online reviews as much as personal recommendations. By prioritizing manufacturers with strong reviews, buyers can mitigate risks and ensure they are investing in reliable, high-performance saw blades.

Evaluating Material Options for Enhanced Durability and Performance

When sourcing high-quality reciprocating saw blades, one of the essential aspects to consider is the material used in their construction. The material not only affects the blade's performance but also influences its durability, which is critical for both professional contractors and DIY enthusiasts. One common choice is high-speed steel (HSS), known for its strength and resilience. HSS blades maintain their sharpness longer than standard steel, making them ideal for a variety of cutting tasks. However, they might struggle with heavier materials, which leads us to consider other options.

Bi-metal blades, which consist of high-speed steel teeth welded to a flexible steel body, offer an excellent solution that balances durability and cutting power. These blades are designed to withstand the rigors of demanding applications without breaking or bending. They are particularly effective for slicing through tough materials like wood with nails or metal, ensuring that users can rely on their performance across diverse projects.

Another innovative material to explore is carbide-tipped blades. These are especially valuable in heavy-duty applications. The carbide tips provide superior hardness, allowing the blades to cut through abrasive materials, such as composites and masonry, with ease. The versatility and longevity of carbide-tipped blades make them an investment worth considering for anyone looking to extend the lifespan of their tools while achieving optimal results. By evaluating these material options, you can select reciprocating saw blades that meet your specific needs for durability and performance.

Tips on Negotiating Prices and Establishing Long-Term Manufacturer Relationships

When sourcing high-quality recip saw blades, negotiating prices and establishing long-term relationships with manufacturers is crucial. According to a recent report by the American National Standards Institute (ANSI), the market for saw blades is expected to grow at a compound annual growth rate (CAGR) of 4.7% from 2021 to 2026. This growth highlights the importance of selecting the right manufacturers who can offer both quality and competitive pricing.

Effective negotiation techniques are essential when dealing with manufacturers. It's valuable to come prepared with industry benchmarks; for instance, research indicates that pricing can vary significantly based on material and quality. A study by the National Association of Manufacturers (NAM) revealed that high-quality carbide-tipped blades could enhance cutting efficiency by up to 30%, allowing for a stronger argument when negotiating cost versus performance.

Building a long-term relationship with your supplier benefits both parties. According to the Harvard Business Review, organizations that foster strong partnerships with their suppliers see a 20% increase in overall performance. Establishing trust through open communication and regular feedback creates an environment where manufacturers are more likely to prioritize your needs, potentially offering better pricing and exclusive deals as volume orders increase. By focusing on these strategies, you not only secure high-quality saw blades but also a reliable partner in your business growth.