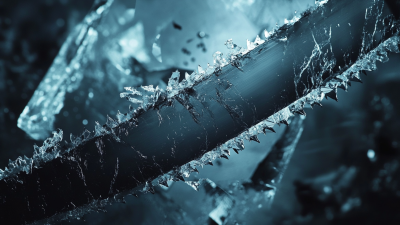

Mastering Recip Saw Blades A Comprehensive Tutorial on Selecting and Using for Optimal Performance

In the world of power tools, adept handling of Recip Saw Blades is crucial for achieving superior cutting performance across various materials. According to recent industry data, the global reciprocating saw market is projected to grow significantly, expected to reach approximately $1.1 billion by 2025, with rising demand across construction and renovation sectors. The choice of the right blade not only enhances efficiency but also significantly impacts the overall project outcome. It is essential for both professionals and DIY enthusiasts to understand the different types of Recip Saw Blades available, their specific applications, and how to pair them with the right tools for optimal results. This comprehensive tutorial will guide you through the critical aspects of selecting and using Recip Saw Blades effectively, ensuring you master your cutting tasks with precision and ease.

Choosing the Right Recip Saw Blade for Your Project Needs

When it comes to tackling various projects, selecting the right reciprocating saw blade is crucial for achieving optimal results. The first step in this process involves understanding the nature of your project. For instance, if you are cutting through wood, choose a blade designed specifically for woodwork, such as a bi-metal or high-speed steel blade that boasts aggressive teeth for fast cuts. On the other hand, when dealing with metal or PVC, a blade with finer teeth made of high-carbon steel or carbide-tipped materials will provide the precision needed for cleaner cuts.

Additionally, consider the thickness of the material you will be cutting. Thicker materials often require a blade with a lower TPI (teeth per inch) to facilitate quicker cuts, while thinner materials benefit from a higher TPI for a smoother finish. Also, pay attention to the blade’s length—longer blades are excellent for deeper cuts, but they may be less maneuverable in tight spaces. By carefully assessing your project's requirements and selecting the appropriate reciprocating saw blade, you can enhance both your efficiency and the quality of your work.

Understanding Different Types of Recip Saw Blades and Their Uses

Selecting the right reciprocating saw blade is crucial for achieving optimal performance in your cutting tasks. Different types of blades are designed for specific materials and applications, making it essential to understand their unique features. For instance, bi-metal blades are versatile and great for cutting wood and metal, while carbide-tipped blades excel in durability and longevity, ideal for tough cutting jobs. Whether you are a professional or a DIY enthusiast, choosing the correct blade can significantly enhance your cutting efficiency.

When using a reciprocating saw, it's important to keep a few tips in mind to maximize your results. First, always match the blade type to the material you are cutting; this will prevent unnecessary wear and tear. Second, maintain a steady pace while cutting to ensure cleaner cuts and minimize overheating the blade. Lastly, invest in high-quality blades where necessary—though they may come with a higher price tag, they often provide better performance and lifespan, ultimately saving you money. With the right blade and techniques, your reciprocating saw can be a powerful ally in any cutting project.

Tips for Properly Maintaining Your Recip Saw Blades for Longevity

When it comes to mastering reciprocating saw blades, maintaining them properly is key to achieving optimal performance and longevity. Regular maintenance can significantly extend the lifespan of your blades, ensuring they remain sharp and effective for all your cutting tasks. Begin by ensuring that you clean the blades after each use. This helps remove any residual material that could dull the teeth or cause corrosion. Additionally, always inspect your blades for wear and tear; replacing damaged or worn blades promptly will prevent them from affecting your work quality.

Another essential tip for maintaining your reciprocating saw blades is to store them correctly. Blade storage can make a substantial difference in preserving their sharpness and overall condition. Keep your blades in a protective case or holder, away from moisture and extreme temperatures. This not only prevents physical damage but also minimizes exposure to elements that can lead to rust. As holiday sales and tool deals become available, it's a great time to invest in new saw blades or even shop for additional tools that can complement your workshop. With the right maintenance practices in place, you'll ensure that your blades perform at their peak for all your future projects.

Mastering Recip Saw Blades: A Comprehensive Tutorial on Selecting and Using for Optimal Performance

| Blade Type | Material | Teeth Per Inch (TPI) | Best Use Case | Maintenance Tips |

|---|---|---|---|---|

| Wood Cutting Blade | High Carbon Steel | 5-7 | Wood, Soft Materials | Keep clean and dry; store in a protective casing. |

| Metal Cutting Blade | Bi-metal | 10-14 | Metal, Pipes, Thin Sheets | Avoid excessive heat; check for damage before use. |

| Demolition Blade | Carbide Tipped | 4-6 | Concrete, Brick, and Heavy Materials | Inspect regularly; clean with a wire brush. |

| Plastic Cutting Blade | High Carbon Steel | 8-10 | Plastic, PVC | Clear residues after use; avoid bending. |

Common Mistakes to Avoid When Using Recip Saw Blades

When using reciprocating saw blades, avoiding common mistakes can substantially improve cutting efficiency and safety. A frequent error is selecting the wrong blade type for the material. Each blade is designed for specific tasks—wood cutting requires different teeth counts and configurations than metal or plastic. Additionally, many users underestimate the importance of blade maintenance; dull or damaged blades can lead to poor performance and can even damage the saw itself.

Another common pitfall is improper technique during cutting. Holding the saw incorrectly or applying excessive pressure can lead to jagged cuts or increase the risk of kickback. It's crucial to maintain a steady grip and let the blade do the work. Finally, many DIYers neglect to check the blade's alignment with the material, which can result in uneven cuts and waste. By being mindful of these common pitfalls, users can enhance their performance and achieve cleaner, more precise cuts with their reciprocating saw blades.

Mastering Recip Saw Blades: Cutting Efficiency Comparison

This chart illustrates the cutting efficiency of various reciprocating saw blade types. Selecting the right blade type can significantly affect work efficiency and results. Avoid common mistakes by understanding these performance metrics.

Enhancing Performance: Accessories and Techniques for Effective Cutting

When it comes to enhancing the performance of reciprocating saws, understanding the right accessories and techniques is crucial. Recent studies in cutting tool design and optimization highlight the importance of integrating innovative materials such as micro-groove structures, which significantly improve cutting efficiency and wear resistance. A numerical simulation combined with experimental data showcases that tools designed with advanced micro-grooves can reduce cutting forces by up to 25%, leading to a longer tool lifespan and better cutting quality.

Utilizing cutting-edge machine learning techniques to optimize supply chain management can also enhance the effective use of these tools in various applications. For example, leveraging predictive analytics enables manufacturers to select the most suitable materials for specific cutting tasks, thereby refining inventory control and reducing production costs. Additionally, recent innovations in energy-efficient materials reveal that incorporating these advancements not only contributes to sustainability but also enhances operational efficiency in the construction industry. This shows that staying informed about the latest technological developments is essential for achieving the best performance from reciprocating saws.

Related Posts

-

Tips for Sourcing High Quality Recip Saw Blades from Manufacturers

-

The Future of Reciprocating Saw Blades in Construction Innovation and Efficiency

-

Unleashing Global Trust in Quality with Best Recip Saw Blades from China

-

Ultimate Guide to Choosing the Right Step Bit for Your Business Needs

-

The Definitive Handbook to Choosing the Perfect Carbide Drill Bit Set for Your Business Needs

-

Comprehensive Technical Specifications for Choosing the Right Drill Bit Set: A Step-by-Step Guide