Innovative Examples of Step Bit Applications in Modern Manufacturing Techniques

In the ever-evolving landscape of modern manufacturing, the need for precision and efficiency drives the adoption of innovative tools and techniques. Among these, the Step Bit has emerged as a critical component in various applications, enhancing productivity while ensuring high-quality results. A recent report from Grand View Research highlights that the global manufacturing tools market is projected to reach USD 228.8 billion by 2025, growing at a CAGR of 5.3%. This growth is partially attributed to advancements in drilling technologies, where Step Bits offer versatility in creating multiple hole sizes with a single tool, thereby reducing setup times and minimizing waste. As manufacturers increasingly seek to streamline their processes and improve output quality, understanding the innovative applications of Step Bits in current manufacturing techniques becomes essential for staying competitive in this dynamic industry.

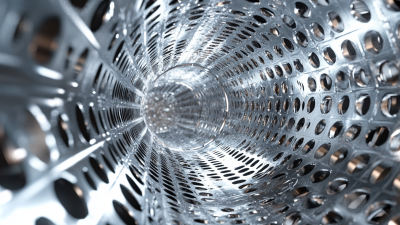

Innovative Design: How Step Bits Enhance Precision Drilling in Aerospace Manufacturing

In the fast-paced realm of aerospace manufacturing, precision and efficiency are paramount. Step bits have emerged as a crucial tool for achieving high accuracy in drilling operations. These specialized drilling tools create holes with varying diameters without the need for multiple bits, streamlining the manufacturing process. A recent report from the Aerospace Industries Association highlighted that companies utilizing advanced drilling methods, including step bits, have increased their throughput by 30%, significantly reducing production times.

Using step bits in aerospace applications not only enhances precision but also minimizes material waste. Their unique design allows for effective chip removal, which is essential when working with lightweight materials such as aluminum and composite substrates commonly found in aircraft manufacturing. As noted in a study by the National Aerospace Laboratory, integrating step bits into the production line has improved hole quality by 25%, ensuring a tighter fit for critical components and enhancing overall structural integrity.

**Tip:** When selecting step bits, consider materials suited for aerospace applications, such as cobalt or carbide-tipped options, to ensure longevity and reduce the risk of breakage during drilling.

**Tip:** Keep your drilling speed optimized; a moderate speed can enhance the step bit’s performance, yielding cleaner holes and prolonging the tool's lifespan.

Innovative Applications of Step Bits in Aerospace Manufacturing

Maximizing Efficiency: The Role of Step Bits in Automating Production Lines

In today's fast-paced manufacturing landscape, automation plays a pivotal role in enhancing productivity and reducing operational costs. Step bits have emerged as essential tools in this evolution, offering significant advantages in drilling processes that directly impact efficiency on production lines. According to a recent industry report, the use of innovative drilling tools such as step bits can increase production speed by up to 30%, allowing manufacturers to meet growing demand without compromising quality.

One of the key advantages of step bits is their ability to create multiple hole sizes with a single tool, which streamlines the manufacturing process and minimizes downtime. This versatility is particularly beneficial in automation, where machine setups need to be optimized for various tasks within minimal timeframes. As stated in a report by the Manufacturing Institute, companies that invest in versatile tooling solutions see an average 20% reduction in equipment changeover times, further solidifying the critical role of step bits in modern production techniques.

Tips for maximizing the efficiency of step bits include ensuring proper lubrication during operation, which can significantly extend tool life and maintain cutting efficiency. Additionally, regularly inspecting step bits for wear and tear can help prevent production delays caused by tool failures. Emphasizing the integration of these tools within automated systems not only enhances performance but also contributes to greater cost savings for manufacturers navigating the complexities of modern production demands.

Cost-Effectiveness: Analyzing the Economic Benefits of Step Bit Applications

In recent years, step bits have become increasingly recognized for their cost-effective applications in modern manufacturing techniques. These specialized drills, designed with a series of progressively larger diameters, enable manufacturers to optimize their operations by reducing the number of tools required for different hole sizes. According to a report by Grand View Research, the global drilling tools market is anticipated to reach $10.5 billion by 2025, indicating a growing trend towards efficient and versatile tools in manufacturing. Step bits significantly contribute to this shift, eliminating the need for multiple drill bits and thereby decreasing both material costs and setup times.

Economically, the benefits of step bit applications extend beyond tool reduction. A study conducted by the Manufacturing Institute reveals that improving manufacturing efficiency can enhance productivity by up to 30%. This efficiency is especially pertinent in industries facing labor shortages, as step bits allow operators to work faster with fewer interruptions for tool changes. Additionally, the durability of step bits, often made from high-speed steel or cobalt, contributes to lower replacement costs and less downtime. As manufacturers increasingly seek to maximize their profits while minimizing expenses, the adoption of step bits stands out as a strategic maneuver aligning with overall economic goals.

Sustainability in Manufacturing: Step Bits and Their Contribution to Material Reduction

The threat of climate change has prompted a significant shift in manufacturing practices, with an increasing emphasis on sustainability. One innovative solution gaining traction is the use of step bits in production processes. These tools not only enhance efficiency but also contribute to material reduction, a vital step towards more sustainable manufacturing. By allowing for precision drilling and the creation of large holes without the need for multiple tools, step bits minimize waste and optimize the use of raw materials.

As countries like Vietnam strive for a circular economy by 2035, integrating technologies like step bits can be pivotal. These bits help manufacturers adhere to policies that promote sustainable production and reduce waste through effective material management. Furthermore, initiatives under green deals in various regions underscore the importance of resource efficiency. Step bits represent a small yet impactful advancement within a broader movement toward sustainable practices, reinforcing the idea that even minor tools can play a critical role in shaping a more environmentally responsible manufacturing landscape.

Innovative Examples of Step Bit Applications in Modern Manufacturing Techniques - Sustainability in Manufacturing: Step Bits and Their Contribution to Material Reduction

| Application Area | Step Bit Type | Material Used | Material Reduction (%) | Sustainability Impact |

|---|---|---|---|---|

| Aerospace Component Manufacturing | Step Drill Bits | Titanium Alloy | 30% | Reduced waste and lower energy consumption. |

| Automotive Production | Multi-step Bit | Aluminum Alloys | 25% | Enhanced efficiency with less scrap material. |

| Construction Industry | Extended Step Bits | Steel | 20% | Promotes longer tool life and reduced raw material use. |

| Electronics Manufacturing | Precision Step Bits | Copper | 15% | Reduces energy footprint during manufacturing processes. |

Future Trends: The Evolving Role of Step Bits in Smart Manufacturing Technologies

In the realm of smart manufacturing technologies, the role of step bits is evolving significantly, reflecting broader industry trends driven by technological innovation. As organizations shift to intelligent production techniques, the need for precision and efficiency becomes paramount. Step bits, with their unique design tailored for drilling varied diameters, are increasingly utilized in the development of advanced manufacturing tools. This adaptability not only enhances operation efficiencies but also aligns with the growing demand for customization in production processes.

Moreover, as industries face pressure to innovate and respond to market changes, step bits are emerging as a pivotal component in smart manufacturing solutions. Companies are harnessing integrated technologies such as IoT, artificial intelligence, and digital twins, leading to more optimized workflows and resource utilization. This shift toward smart manufacturing, characterized by collaboration across sectors, showcases how conventional tools like step bits can lead to significant advancements in both productivity and sustainability, ultimately contributing to the industry's future competitive landscape.

Related Posts

-

Ultimate Guide to Choosing the Right Step Bit for Your Business Needs

-

Unveiling the Technical Specifications of the Best Step Bit for Ultimate Precision

-

Innovative Applications of Best Metal Hole Cutters in Construction and Their Challenges

-

Exploring Opportunities for Carbide Hole Saw Manufacturers at the Successful 137th Canton Fair

-

Exploring the Future of Metal Cutting Technologies and Advantages of Best Metal Saw Blades in 2025

-

Essential Techniques for Maximizing the Use of Saw Blades