Exploring the Future of Metal Cutting Technologies and Advantages of Best Metal Saw Blades in 2025

The metal cutting industry is poised for transformative growth, with predictions suggesting a compound annual growth rate (CAGR) of 6.2% from 2020 to 2027, according to a recent report by Grand View Research. As we move into 2025, the advancements in metal cutting technologies and the implementation of innovative materials will significantly enhance efficiency and precision.

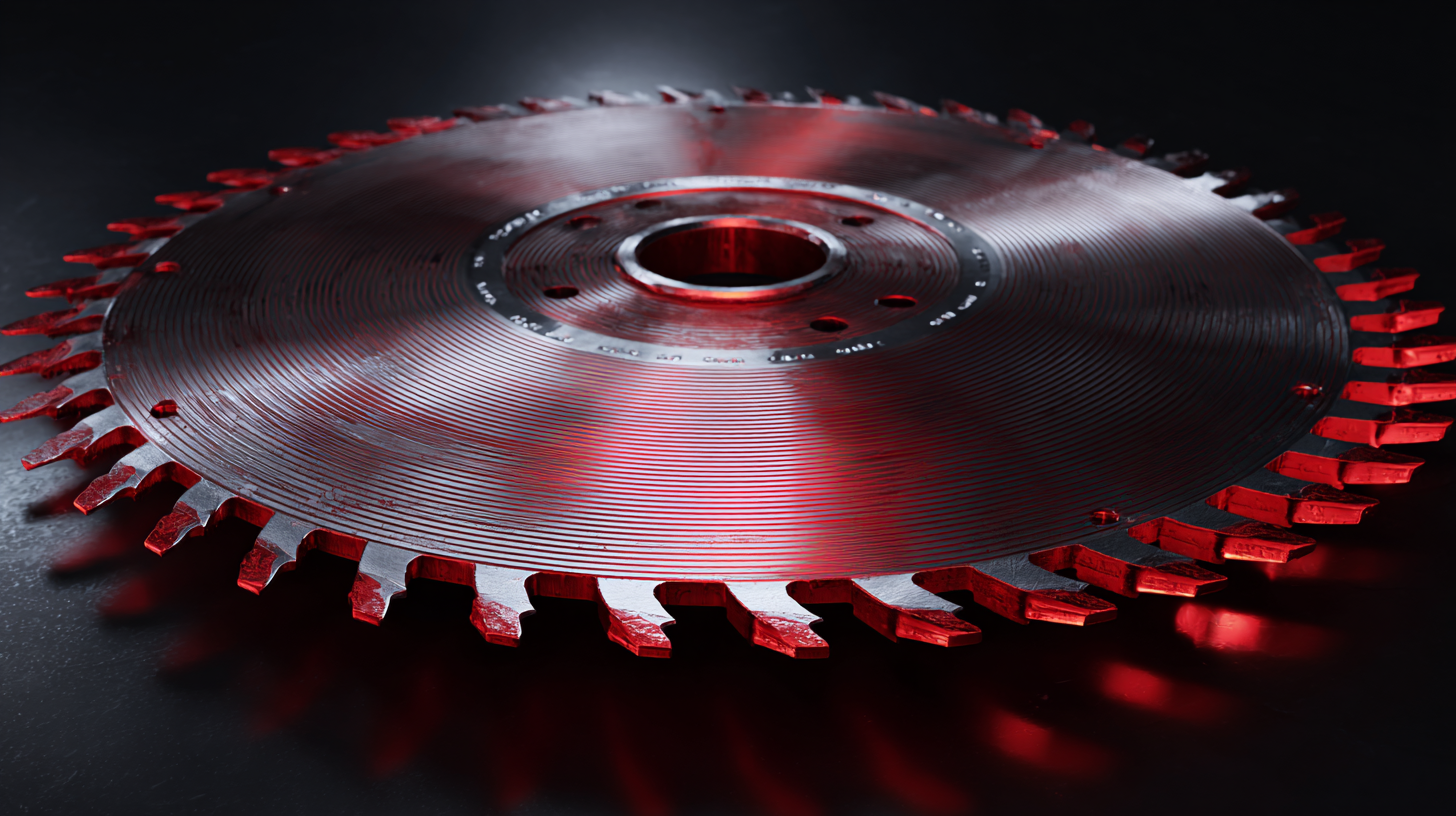

Among these innovations, the role of the Metal Saw Blade will be pivotal, offering superior cutting capabilities that not only boost productivity but also ensure cost-effectiveness for manufacturers. With increasing demand across sectors such as automotive, aerospace, and construction, an understanding of the best practices in choosing and utilizing metal saw blades is essential for professionals aiming to maintain a competitive edge.

This article delves into the future of metal cutting technologies and the advantages offered by premium metal saw blades, while also highlighting the importance of industry certifications that govern imports and exports within the sector.

The Evolution of Metal Cutting Technologies: A 2025 Perspective

As we venture into 2025, the landscape of metal cutting technologies is witnessing significant advancements, driven by the integration of automation, artificial intelligence, and innovative materials. These developments not only enhance precision and efficiency but also redefine the capabilities of metalworking industries. The evolution of software and hardware means that tools are now better equipped to handle complex projects with greater accuracy, which ultimately leads to reduced waste and enhanced productivity.

**Tip:** When selecting metal saw blades, consider not just the material but also the applications they will serve. High-speed steel blades, for example, are optimal for cutting softer metals, while carbide-tipped blades excel in hard materials. This selection can significantly impact the quality of your cuts and the longevity of your tools.

Moreover, the shift towards sustainable practices is prompting manufacturers to develop blades that generate less waste and require less energy during production. Newer blade technologies are designed to maximize performance while minimizing their environmental footprint, aligning with the growing emphasis on sustainability in metal cutting operations.

**Tip:** Regular maintenance of your metal saw blades can enhance their lifespan and performance. Sharpening blades whenever necessary and ensuring they are clean help maintain cutting efficiency and precision over time, making your operations more sustainable and cost-effective.

Key Features and Innovations in Modern Metal Saw Blades

In 2025, the landscape of metal cutting technologies is set to be revolutionized, particularly through advancements in saw blade design and manufacturing. Modern metal saw blades are being engineered with innovative features that enhance performance, durability, and precision. One of the key innovations includes the use of advanced materials, such as high-speed steel (HSS) and carbide-tipped blades, which allow for higher cutting speeds and extended tool life. These materials provide excellent heat resistance, reducing wear and tear on the blade, making them ideal for high-volume production settings.

Another significant feature of contemporary metal saw blades is the incorporation of specialized coatings. These coatings, such as titanium nitride or diamond-like carbon, not only reduce friction during cutting but also prevent chip build-up, which can compromise the cutting ability. Additionally, advancements in tooth geometry, including variable pitch and alternate top bevel designs, contribute to smoother cuts and reduced vibration. As manufacturers continue to push the envelope in blade technology, these innovations will not only improve cutting efficiency but also lead to enhanced safety and lower operational costs for businesses in the metalworking industry.

Comparing Traditional vs. Advanced Metal Cutting Techniques

As we delve into the realm of metal cutting techniques, it's essential to understand the distinctions between traditional and advanced methods. Traditional metal cutting techniques, such as manual sawing and standard band saws, have been the backbone of metalworking for decades. While they are reliable and effective for many applications, these methods often lack efficiency in terms of speed and precision. The craftsmanship involved can result in variations in cut quality, which may not meet the demand for high precision in modern manufacturing settings.

In contrast, advanced metal cutting techniques leverage cutting-edge technologies like laser cutting, waterjet machining, and automated band saws. These advanced methods provide enhanced precision and reduced waste, significantly improving productivity. For instance, laser cutting can achieve intricate designs and tight tolerances without the need for extensive post-processing. Moreover, while traditional methods often require considerable physical effort and time, advanced technologies enable quicker setups and faster processing times, allowing manufacturers to meet tight deadlines and increasing their competitive edge in the market. As we look towards 2025, the shift toward these advanced techniques is set to revolutionize the metalworking industry, ultimately leading to improved product quality and operational efficiency.

The Impact of Material Science on Metal Cutting Efficiency

The impact of material science on metal cutting efficiency is profound, especially as we approach 2025. As researchers delve deeper into the properties of advanced materials, novel solutions emerge to enhance metal cutting technologies. For instance, the exploration of amorphous metals has unlocked new potentials for creating more efficient motors, while their unique characteristics allow for more streamlined cutting processes, reducing heat and improving precision. By leveraging these advancements in material science, manufacturers can significantly boost productivity and transition to greener practices.

Tip: When selecting metal saw blades, consider those specifically designed for cutting new composite materials, as their unique geometries and coatings can improve performance and lifespan.

In addition to traditional approaches, innovative tooling methods are gaining traction, demonstrating how to make challenging materials, such as titanium alloys, easier to cut. By integrating cutting-edge techniques and materials, the industry can address not only efficiency but also the versatility required for future applications. This evolution highlights the necessity for ongoing investment in material research, ensuring that metal cutting technologies keep pace with the demands of modern manufacturing.

Tip: Always stay abreast of new developments in material science, as adopting advancements early can provide a competitive advantage in precision engineering tasks.

Cost-Effectiveness and Environmental Benefits of Modern Metal Saws

The modern evolution of metal saws is leading us toward a more cost-effective and environmentally friendly future. As the industry pivots towards sustainability, new metal cutting technologies are proving that efficiency does not have to come at an environmental cost. Advanced metal saw blades now utilize materials and designs that reduce waste, ensuring that they last longer and cut cleaner. This not only saves money on repeat purchases but also minimizes the environmental impact associated with production and disposal.

Tip: When selecting metal saw blades, consider those made from high-speed steel or carbide-tipped options. These materials enhance durability and efficiency, allowing for precise cuts with less energy consumption.

Moreover, transitioning to state-of-the-art metal saws can significantly lower operational costs. These saws are engineered for reduced power consumption and faster cutting speeds, translating into lower utility bills and increased productivity. Companies that invest in such technology find that their return on investment is often realized quickly through savings on both material and labor costs.

Tip: Regular maintenance and proper usage of metal saws can further extend their lifespan. Always follow manufacturer guidelines and invest time in routine checks to keep the equipment running smoothly.