How to Choose the Right Metal Hole Cutter for Your Next DIY Project

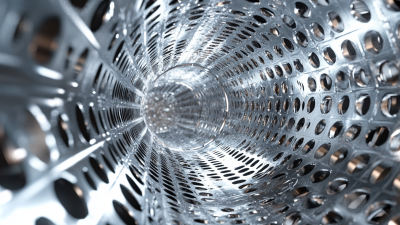

When embarking on a DIY project that requires precision and durability, selecting the right tools is crucial, and one of the key components is the Metal Hole Cutter. This versatile tool is designed to create clean, round holes in various types of metal surfaces, making it an essential choice for anyone working on projects ranging from home renovations to automotive repairs.

However, with the wide variety of options available, choosing the appropriate Metal Hole Cutter can be overwhelming. Factors such as material type, size, and specific application needs must be carefully considered to ensure optimal performance and results.

This guide aims to walk you through the essential aspects of selecting the right Metal Hole Cutter, equipping you with the knowledge to make an informed decision that aligns with your project requirements and ultimately enhances your DIY experience.

Understanding Different Types of Metal Hole Cutters and Their Applications

When embarking on a DIY project that requires cutting metal, understanding the different types of metal hole cutters and their applications is crucial. Metal hole cutters primarily come in three varieties: twist drill bits, hole saws, and step bits. According to a report by the Manufacturing Institute, more than 70% of metalworking projects in the United States involve the use of these tools. Twist drill bits are primarily used for creating smaller diameter holes, perfect for precision tasks, while hole saws are ideal for larger cuts, efficiently removing larger sections of metal. Step bits, on the other hand, are versatile and can create multiple hole sizes with one tool, increasingly popular in home projects.

Tips: When selecting a hole cutter, consider the thickness of the metal and the desired hole size. It's important to use the right RPM setting on your drill; for instance, slower speeds are recommended for harder metals to prevent overheating and dulling the cutter. Additionally, always ensure you have a proper setup to secure the metal being worked on, as improper handling can lead to accidents.

It's also worth noting the material of the cutter itself. High-speed steel (HSS) bits are common due to their durability, but cobalt and carbide-tipped hole cutters are becoming increasingly favored for tougher applications. According to the International Tool Manufacturers Association, cobalt bits can last up to 10 times longer than standard HSS bits when cutting through challenging metals. Always match your hole cutter's material with your project requirements for optimal performance.

Key Factors to Consider When Selecting a Metal Hole Cutter for DIY Projects

When selecting a metal hole cutter for your DIY project, several key factors come into play to ensure you choose the right tool for your specific needs. First and foremost, consider the material you will be cutting. Different hole cutters are designed for varying metal types, such as aluminum, steel, or even stainless steel. Make sure to select a cutter that is suitable for the hardness and thickness of the metal you are working with, as this will greatly impact both the efficacy of the cut and the longevity of the tool.

Another important factor is the diameter of the hole you need. Metal hole cutters come in various sizes, so it’s essential to determine the exact diameter required for your project. Additionally, consider the type of drill you will be using. Some cutters are compatible with standard drills, while others may require a more specialized tool. Lastly, pay attention to the cutting speed and technique. Choosing a cutter with the correct tooth design can optimize cutting efficiency, reducing heat buildup and ensuring a smoother finish. By taking these factors into account, you can confidently select the right metal hole cutter to achieve outstanding results in your DIY project.

How to Choose the Right Metal Hole Cutter for Your Next DIY Project

| Feature | Importance | Considerations |

|---|---|---|

| Material Compatibility | High | Ensure the cutter is suitable for the metal type being used (e.g., steel, aluminum). |

| Diameter options | Medium | Select a cutter that offers the required diameter for your project. |

| Cutting Depth | High | Check if the cutting depth is adequate for the thickness of the metal. |

| Type of Hole Cutter (e.g., Hole Saw, Punch) | Medium | Choose the right type based on the project requirements and ease of use. |

| Durability | High | Select a cutter made from high-quality materials for long-lasting use. |

| Ease of Use | Medium | Look for user-friendly designs for a straightforward DIY experience. |

Analyzing Material Compatibility: Choosing the Right Cutter for Different Metal Types

When embarking on a DIY project involving metal work, understanding material compatibility is crucial for selecting the right metal hole cutter. Different metals, such as aluminum, stainless steel, and mild steel, require specific types of cutters to achieve optimal results. For instance, while high-speed steel (HSS) cutters are often effective for softer metals like aluminum due to their sharp edges and ability to retain cutting efficacy at higher speeds, they may struggle with harder materials. According to a recent report by the Tool and Die Association, using the appropriate cutter can increase efficiency by up to 30%, effectively reducing both time and material waste.

In contrast, bi-metal hole saws are recommended for tougher metals like stainless steel. These saws combine HSS with a tougher backing material, providing the durability needed to handle high temperatures and resist wear during prolonged use. A study published in the Journal of Materials Processing Technology highlights that bi-metal cutters last up to 50% longer than standard steel options when cutting harder materials. Therefore, assessing the metal's properties and using the right cutting tool is not just a matter of convenience but a key factor in ensuring the longevity of both the tool and the workpiece.

Evaluating Cutter Sizes and Their Impact on Project Precision and Finish

When selecting a metal hole cutter for your DIY project, evaluating cutter sizes is crucial for achieving both precision and a quality finish. The diameter of the cutter determines the size of the hole produced, impacting not only the fit of components but also the overall aesthetics of the final product. For projects requiring tight tolerances, opting for a cutter that matches the required hole size closely can significantly improve the accuracy of your work. Additionally, larger cutters often create more debris, which means proper technique and adequate cleanup are essential to maintain precision.

The impact of hole cutter size extends beyond mere dimensions; it also influences how cleanly the hole is finished. A well-sized cutter reduces the likelihood of jagged edges and uneven surfaces, which can detract from the professional appearance of your project. When possible, utilize pilot holes or tiered cutting techniques with different sizes to gradually achieve the desired hole. This approach not only preserves the integrity of the metal but also enhances the quality of the finish, making your DIY project look polished and expertly crafted. Selecting the right size should always balance functionality with the desired finish to ensure a successful outcome.

Impact of Metal Hole Cutter Sizes on Project Precision

This chart shows the impact of different metal hole cutter sizes on project precision. As the size of the cutter increases, the precision tends to decrease due to factors such as material stability and cutter quality.

Performance Metrics: How Tooth Design and Speed Affect Cutting Efficiency

When selecting a metal hole cutter for your DIY project, understanding how tooth design and speed influence cutting efficiency is crucial. Studies have shown that a cutter's tooth geometry can significantly impact its performance. For instance, cutters with a progressive tooth design, which gradually increases in size, have been shown to yield smoother cuts and reduce vibration during operation. According to a report from the Metal Cutting Association, such designs can improve cutting speed by up to 30% compared to traditional straight-tooth cutters, especially when working with tougher materials like stainless steel or hardened metals.

Additionally, the speed at which the hole cutter is operated plays an essential role in efficiency. A speed range of 2000-3000 RPM is often recommended for achieving optimal results with metal hole cutters. Operating within this speed range can enhance chip removal and minimize heat buildup, ultimately prolonging the tool's lifespan. Data from the National Institute of Standards and Technology indicates that for each increase of 100 RPM, cutting performance can improve by approximately 5%. Therefore, when choosing a metal hole cutter, assessing both the tooth design and the operational speed will ensure that you achieve the best possible outcome for your project.

Related Posts

-

Innovative Applications of Best Metal Hole Cutters in Construction and Their Challenges

-

Exploring Opportunities for Carbide Hole Saw Manufacturers at the Successful 137th Canton Fair

-

How to Maximize the Value of Your Best Metal Hole Saw with Cost Effective After Sales and Maintenance Solutions

-

Ultimate Guide to Choosing the Right Metal Cutting Blade for Your Project

-

The Definitive Handbook to Choosing the Perfect Carbide Drill Bit Set for Your Business Needs

-

Unveiling the Technical Specifications of the Best Step Bit for Ultimate Precision