How to Choose the Right Saw Blades for Your Cutting Needs

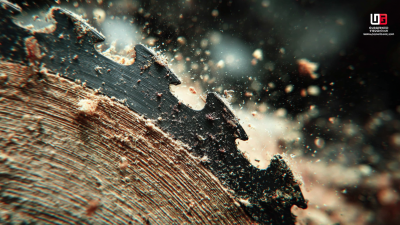

In the realm of woodworking and construction, the importance of selecting the right saw blades cannot be overstated. According to a recent report by the Woodworking Industry Association, improperly chosen saw blades can lead to a significant increase in cutting defects, resulting in up to 30% more waste material and decreased efficiency on job sites. With a myriad of options available, from carbide-tipped to high-speed steel, understanding the specific cutting needs of your projects is essential for achieving precision and quality.

Choosing the right saw blades not only enhances productivity but also extends the longevity of your tools. As industry standards evolve, equipping yourself with the knowledge to select appropriate saw blades will ultimately contribute to better craftsmanship and successful project outcomes.

Choosing the right saw blades not only enhances productivity but also extends the longevity of your tools. As industry standards evolve, equipping yourself with the knowledge to select appropriate saw blades will ultimately contribute to better craftsmanship and successful project outcomes.

Understanding Different Types of Saw Blades for Various Materials

When it comes to selecting the right saw blades for your cutting needs, understanding the different types of saw blades is crucial. Saw blades are designed specifically for various materials, and using the wrong blade can lead to inefficient cuts and even damage to both the material and the saw itself. For example, a carbide-tipped blade is ideal for cutting hardwood, as its durability allows it to handle the density of the wood without dulling quickly. According to a report by the Woodworking Machinery Industry Association, using the correct blade can increase cutting efficiency by over 30%.

Tips: Always consider the tooth count when selecting a blade. A higher tooth count typically provides a smoother finish, making it suitable for delicate work, while fewer teeth remove material more rapidly, ideal for rough cuts. Additionally, familiarize yourself with the various types of teeth styles—such as flat-top, alternating top bevel, and combination—to match your specific cutting needs.

When working with metal, a bi-metal or high-speed steel blade is recommended, as they are designed to withstand the heat generated during cutting. Research from the Metal Cutting Technology Association indicates that using the appropriate blade material can enhance blade life by 40% or more. Maintaining sharp blades will not only improve the quality of your cuts but also increase your safety during operation. Regularly inspect and replace dull blades to keep your projects on track.

Key Factors to Consider When Selecting Saw Blades

When selecting saw blades for your cutting needs, several key factors should guide your decision. First, consider the material you will be cutting. Different materials, such as wood, metal, or plastic, require blades designed specifically for their properties. For instance, a carbide-tipped blade is ideal for cutting through hardwoods, while a bi-metal blade excels at metal cutting. Understanding these material requirements is essential to achieving clean and efficient cuts.

When selecting saw blades for your cutting needs, several key factors should guide your decision. First, consider the material you will be cutting. Different materials, such as wood, metal, or plastic, require blades designed specifically for their properties. For instance, a carbide-tipped blade is ideal for cutting through hardwoods, while a bi-metal blade excels at metal cutting. Understanding these material requirements is essential to achieving clean and efficient cuts.

Next, pay attention to the blade teeth configuration. The number of teeth and their shape play crucial roles in the cutting performance. Blades with fewer teeth, such as those designed for ripping wood, provide faster cuts but may result in rougher edges. In contrast, blades with more teeth offer smoother finishes, making them suitable for crosscuts and delicate work. Additionally, factors such as the tooth geometry—whether they're flat ground, alternate top bevel, or triple chip grind—can greatly influence the blade's efficiency and longevity. By assessing your specific cutting tasks, you can choose the most effective blade for your projects.

How Tooth Design Affects Cutting Performance

When selecting the right saw blades, understanding the tooth design is essential for achieving optimal cutting performance. The shape, size, and arrangement of the teeth significantly influence how efficiently a blade operates. For instance, blades with fewer teeth cut faster but produce rougher edges, making them suitable for tasks like rough cutting or demolition. In contrast, blades with more teeth yield smoother finishes, ideal for fine woodworking or precision cuts.

**Tip:** When choosing a saw blade, consider the material you'll be cutting. For softer materials like pine, a blade with fewer, larger teeth will work well, while harder materials, such as hardwoods or composites, benefit from blades with more teeth for cleaner cuts.

Moreover, the type of tooth design—rake angle and hook angle—plays a critical role in determining the blade's cutting action. A positive rake angle allows for aggressive cutting, making it effective for softer materials, whereas a negative rake angle is better for cutting harder substances, as it reduces the chance of binding and promotes control.

**Tip:** Always match your blade’s tooth design to the specific cutting requirements of your project to enhance efficiency and the quality of your work.

How to Choose the Right Saw Blades for Your Cutting Needs - How Tooth Design Affects Cutting Performance

| Tooth Design | Application | Material | Cutting Speed (sfm) | Finish Quality |

|---|---|---|---|---|

| Alternate Top Bevel (ATB) | Cross-cutting wood | Hardwood | 3000 | Smooth |

| Flat Top (FT) | Ripping lumber | Softwood | 3500 | Rough |

| Triple Chip Grind (TCG) | Aluminum and composites | Aluminum | 4000 | Good |

| Hook Angle | Fast feed rates | Plywood | 3200 | Medium |

Importance of Blade Thickness and Width for Your Projects

When selecting saw blades for your cutting needs, understanding the importance of

blade thickness and

width can significantly impact the outcome of your projects.

The thickness of a saw blade determines the kerf, which is the width of the cut made.

Thinner blades produce less waste and are ideal for precision cuts, while

thicker blades provide more stability, making them suitable for

heavy-duty tasks. For intricate work, consider using a blade that balances both

thinness for minimal damage to the material while offering a sufficient width for durability.

In addition to thickness, the width of the blade also plays a crucial role in its performance.

Wider blades tend to be more rigid, reducing flex during cuts and

ensuring straighter, more accurate lines. On the other hand,

narrower blades are better for curves and detailed work.

When choosing a blade, assess the material you will be cutting: harder materials may benefit from

thicker, wider blades that can withstand greater stress, while softer materials allow for

more versatility with thinner blades.

Tips: Always check the manufacturer's

specifications for your saw to ensure compatibility with the chosen blade. For projects requiring

intricate cuts, have a selection of both wide and narrow blades on hand to switch as needed.

Remember that proper blade maintenance, including regular sharpening, is essential for achieving

the best results!

Essential Maintenance Tips to Extend the Life of Your Saw Blades

When it comes to maintaining saw blades, proper care is essential for extending their lifespan and ensuring optimal performance. According to a report by the Woodworking Machinery Industry Association, well-maintained saw blades can last up to three times longer than those that are neglected. Regular cleaning is one of the easiest yet most effective ways to prolong the life of your blades. Using a blade cleaning solution can remove pitch and resin buildup, which, if left untreated, can lead to premature dulling and ineffective cutting.

Additionally, ensuring correct storage can significantly enhance the longevity of your saw blades. Research shows that improper storage can cause blades to warp, impacting their cutting accuracy. To prevent this, blades should be stored in a protective case or on a blade rack, away from moisture and extreme temperatures. Furthermore, regularly checking for any signs of wear, such as chips or missing teeth, can help catch issues early, allowing for timely sharpening or replacement, which ultimately adds to the overall efficiency and effectiveness of your cutting tasks.

Related Posts

-

Exploring the Future of Metal Cutting Technologies and Advantages of Best Metal Saw Blades in 2025

-

Ultimate Guide to Choosing the Best Saw Blades for Wood in Your Global Sourcing Strategy

-

8 Best Carbide Tipped Drill Bits to Elevate Your Drilling Experience

-

The Future of Reciprocating Saw Blades in Construction Innovation and Efficiency

-

Ultimate Guide to Choosing the Right Metal Cutting Blade for Your Project

-

Mastering Precision Cuts: A Comprehensive Guide to Choosing the Best Jigsaw Blades for Any Project