How to Choose the Right Bandsaw Blades for Your Cutting Needs

When it comes to selecting the appropriate bandsaw blades for your specific cutting needs, understanding the intricacies of blade types and materials is essential. According to recent industry reports, the global bandsaw blade market is projected to reach over $550 million by 2026, reflecting significant growth driven by advancements in blade technology and increasing demand across manufacturing sectors. Choosing the right bandsaw blades not only enhances cutting efficiency but also impacts the quality of the finished product and operational costs.

Factors such as blade width, tooth configuration, and material type play pivotal roles in optimizing performance for various applications, whether it be for wood, metal, or composite materials. Therefore, making an informed decision regarding bandsaw blades is crucial for achieving accurate cuts, prolonging blade life, and ultimately ensuring productivity in your workshop or manufacturing environment.

Understanding Different Types of Bandsaw Blades for Various Materials

When selecting bandsaw blades, understanding the various types available is crucial for achieving optimal cutting performance on diverse materials. Bi-metal band saw blades, which currently hold a significant share in the market due to their versatility, have specific features that make them suitable for cutting metals, plastics, and wood. According to industry reports, the bi-metal segment is projected to grow substantially, particularly in sectors requiring durable and efficient cutting solutions.

Different tooth types—regular, hook, and skip—also play a pivotal role in the choice of blades. Regular tooth blades are ideal for straight cuts in wood, while hook tooth blades are designed for fast cutting in thicker materials. Skip tooth blades, on the other hand, are perfect for cutting softer materials as they promote faster chip removal. Industry data indicates that the choice of tooth type can enhance productivity by reducing material waste and ensuring smoother finishes.

Tips: When selecting a bandsaw blade, consider the material you will be cutting and the thickness of that material. Matching the tooth type to your specific application will ensure better results. Additionally, be mindful of blade width; wider blades provide stability for straight cuts, while narrower blades are more suited for intricate curves.

Factors to Consider for Selecting Bandsaw Blades Based on Cutting Style

When selecting bandsaw blades, it's crucial to consider how your cutting style will influence your choice. Factors such as the material being cut, required blade width, and tooth configuration all play significant roles in determining the most suitable blade for your needs. For instance, if you are operating within the pallet manufacturing and sawmill industries, where horizontal bandsaws are commonplace, focusing on resawing abilities becomes essential. Choosing a blade designed specifically for resawing can greatly enhance efficiency and precision when cutting through materials like cants and low-grade lumber.

Additionally, the blade's tooth count and geometry should be tailored to the thickness and hardness of the material you are working with. A lower tooth count with larger gullets may be ideal for heavy resaw work, allowing for better chip clearance, while finer teeth are preferable for smoother cuts on softer materials. Being mindful of these factors will ensure that you select a bandsaw blade that aligns with both your operational requirements and desired cutting outcomes.

How Blade Width and Tooth Count Affect Cutting Performance

When selecting the right bandsaw blade, the width and tooth count play pivotal roles in determining cutting performance. A blade’s width influences its ability to make smooth, precise cuts on various materials. Generally, wider blades (typically 1 inch or more) are favored for straight cuts in thick materials, as they provide better stability and reduce the risk of bending. Conversely, narrower blades (around 1/4 inch) excel in making intricate cuts and curves, allowing for greater maneuverability. The Woodworking Industry report from 2022 indicates that over 60% of woodworkers prefer narrower blades for intricate designs, while 75% of metalworkers opt for wider blades to handle tougher materials effectively.

Tooth count is another critical aspect in blade selection, as it determines the cutting efficiency and finish quality. Blades with fewer teeth per inch (TPI) can remove material faster, making them ideal for cutting softer materials or when speed is essential. In contrast, blades with a higher TPI (10-14 TPI) provide smoother finishes and are best suited for cutting harder woods and plastics. According to a recent survey by the Band Saw Institute, a staggering 80% of professional woodworkers reported that higher TPI blades resulted in superior cut quality, enhancing their overall productivity. Understanding the balance between blade width and tooth count allows users to tailor their bandsaw setups to their specific cutting applications.

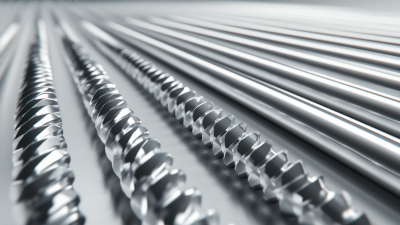

Evaluating Blade Coatings for Enhanced Durability and Efficiency

When selecting bandsaw blades, one critical aspect to consider is the blade coating, which significantly influences durability and cutting efficiency. Various coatings, such as titanium or carbide, can enhance the lifespan of the blade and allow for smoother cuts through different materials. A good coating reduces friction, minimizes heat buildup, and helps prevent rust and corrosion, which is particularly beneficial for blades subjected to continuous use or challenging environments.

**Tips:** When choosing a blade coating, assess the material you will be cutting. For instance, if you frequently work with hardwoods, a blade with a carbide coating can withstand tougher conditions and provide a clean cut. Conversely, if you’re dealing with softer materials, simpler coatings might suffice, balancing performance and cost-effectiveness. Also, consider the type of cutting—metalwork may benefit more from specialized coatings that provide superior edge retention.

Opting for a coated blade may initially seem more expensive, but it often saves time and money in the long run, as it reduces the frequency of blade replacements. Always compare the features of different coatings to find the right match for your specific cutting needs and enhance your woodworking or metalworking projects.

Blade Coating Performance Comparison

Top Brands and Their Best-Selling Bandsaw Blades Reviewed

When selecting bandsaw blades, understanding the strengths of top brands can significantly enhance your cutting efficiency. According to a recent report by the Woodworking Network, brands like Olson and Timber Wolf are consistently recognized for their premium quality and longevity. Olson’s blades, marketed for their high cutting speed and accuracy, boast a user satisfaction rate of over 90%, making them a favorite among woodworkers. Their resaw blades, designed to cut thin panels, have received acclaim for producing smooth finishes while minimizing waste.

Another standout brand is Timber Wolf, known for its unique proprietary process that enhances blade flexibility and reduces breakage. Their blades are recommended for both metal and wood cutting applications, with a significant increase in productivity reported—up to 20% faster cuts compared to standard blades. Furthermore, their customers have noted a reduction in blade wear, which is crucial for maintaining operational efficiency in any workshop. With these insights from industry reports, understanding the offerings of these renowned brands can guide you toward selecting the most appropriate bandsaw blades tailored to your specific cutting needs.

How to Choose the Right Bandsaw Blades for Your Cutting Needs

| Blade Type | Material | Teeth per Inch (TPI) | Best for Cutting | Overall Rating |

|---|---|---|---|---|

| Traditional Carbon | Carbon Steel | 3-24 | Wood | 4.5/5 |

| Bi-Metal | High-Speed Steel | 10-14 | Metal | 4.7/5 |

| Cobalt | Cobalt Steel | 14-24 | Thicker Metals | 4.8/5 |

| Flexback | Flexible Steel | 4-6 | Curved Cuts | 4.3/5 |

| Hard Back | High Carbon | 6-10 | Laminates | 4.6/5 |

Related Posts

-

Mastering Your DIY Projects with the Ultimate Guide to Choosing Drill Bit Sets

-

Mastering Recip Saw Blades A Comprehensive Tutorial on Selecting and Using for Optimal Performance

-

Exploring the Future of Metal Cutting Technologies and Advantages of Best Metal Saw Blades in 2025

-

Understanding the Benefits of Long Drill Bits for Your Manufacturing Needs

-

Essential Techniques for Maximizing the Use of Saw Blades

-

Exploring Opportunities for Carbide Hole Saw Manufacturers at the Successful 137th Canton Fair